Braille display demo refreshes with miniature fireballs

There have been a lot of advances in accessibility recently, with voice control, screen readers, and more improving access to computers for many people. But something that’s been missing is a haptic device, which provides touch-based information—think of a dynamic Braille display. For many people, notably those with limited vision and hearing, this would be the most effective way of interacting with electronics. And a simple, low-cost haptic device can have plenty of applications beyond accessibility.

One of the reasons these haven’t become widely available is that they’re hard to make. Physical actuators that can create a pattern detectable by touch take up a fair bit of volume and are difficult to pack into close proximity to each other. They also tend to be pricy. So, a US-Israeli team of researchers looked into alternatives to physical hardware. And the researchers came up with an unexpected alternative: set off a miniature fireball inside a flexible bit of polymer that can inflate like a balloon.

Replacing hardware with combustion

In theory, making a refreshable Braille display is relatively easy. All we need is an array of mechanical devices that can be switched between up and down states. The reason these don’t exist is that the mechanical devices that are commercially available are too bulky to place in close proximity. For example, the researchers consider the possibility of using microfluidics to inflate a polymer bubble. But the valves needed for a 2 x 3 grid of devices would occupy 18 times the area of the device itself and cost about $250.00.

An actual row of these devices with sufficient resolution to replicate a line of Braille text would be prohibitively expensive and require a complicated three-dimensional arrangement of valves and tubing.

It might be possible to engineer a custom array of mechanical devices that could fit in the required state. But the team behind the new work decided to skip the mechanical hardware entirely. Instead, the researchers decided to try combustion.

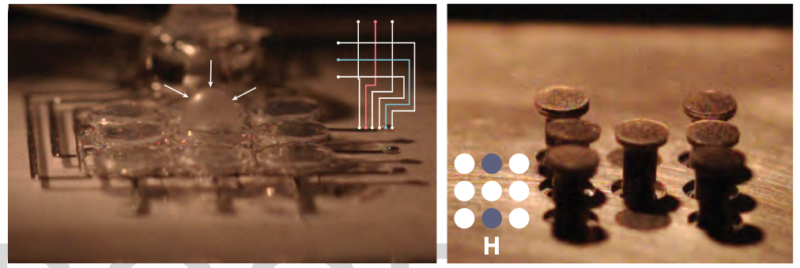

The basis of their hardware is a small, deformable polymer with tiny raised areas that are able to repeatedly inflate like balloons and deflate later. Underneath, the researchers had a system of channels that fed a mixture of methane and oxygen to each of these polymer bubbles. And, at the base of the bubble, they had two wires that could carry enough current to allow a spark between them. These were made of liquid gallium, which allowed the device to be flexible and also allows a degree of self-repair.

The spark ignites the mixture of gasses, causing a sudden increase in pressure—the researchers haven’t determined if there’s an actual detonation, but the combustion is powerful enough to create an audible noise. The pressure it generates expands the bubble above, creating a change in the surface that can be perceived by touch. And, by expanding, the polymer drops the pressure the recently combusted gasses experience, which will cause their temperature to drop. In essence, the device itself serves as a cooling system for the combustion, keeping it from building up heat.

A few small issues

The problem with the combustion turned out to be on the other end of the device, where the fuel is fed into it. Here, the researchers observed that the combustion spread into the feed lines and eventually burned through the entire device. The team knew that this is typically prevented by putting a filter with small pores in the feed line. But the flames here moved so quickly this didn’t work initially, forcing the researchers to shift to larger filters until the burn-back stopped.

The other problem is that, if you continually run a series of small explosions in order to keep the device inflated, you’ll counteract the dissipation of heat provided by the inflation itself. So, while the wires were able to spark at a very high frequency, you don’t actually want to use that to keep the device in its active state.

To work around this, the researchers included a magnetically latched pin within the device. Once the polymer expanded due to the combustion, the pin would shoot upward and latch in place. To reset the device, it would have to be physically depressed again. They demonstrated a working 3 x 3 prototype that could display a variety of simplified characters.

The need to physically reset the device is probably not as much of a limit as it might seem. You can imagine a device where the user gets a chance to feel the haptic information, then depresses the raised devices in order to reset it. Once reset, that can serve as a trigger for the next character to be displayed.

The bigger issue is probably the use of fuel. The researchers are right that we live with fuel all around us. “We acknowledge that some may find the thought of being so close to combustible chemicals unsettling,” they write, “yet we note that billions of liquid butane lighters have rested in people’s front pockets since the 1800s.” The question is more whether it’s practical to expect people to pop a fuel cartridge into their display every few weeks.

Beyond the practicality, however, it’s nice to see work on this area, since there are plenty of other contexts where haptic feedback can be valuable, including various augmented and artificial reality.

PNAS, 2021. DOI: 10.1073/pnas.2106553118 (About DOIs).

https://arstechnica.com/?p=1797198