Jaguar’s Formula E team is a good example of how racing improves road EVs

LONDON—On Wednesday, Jaguar Racing became the latest Formula E team to unveil its race car for the coming season. The sport has radical new technical rules for its third-generation race car, which is smaller, lighter, more powerful, and more efficient. This will be the British automaker’s sixth season competing in the series, and its participation is for more than just marketing; Jaguar Land Rover’s electrified road cars have benefited in tangible ways as a result, according to the team’s technical manager, Phil Charles.

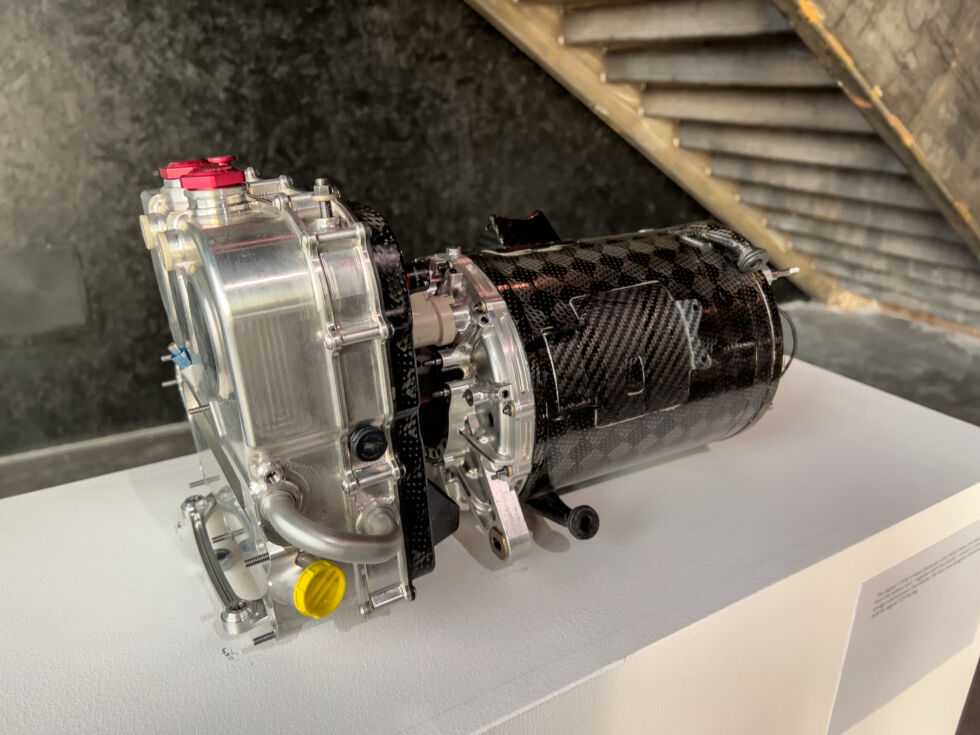

“If you rewind back to 2017, that’s the first time that [we used] our in-house inverter for the racing team,” Charles told Ars. “We put a silicon carbide switching device, the Wolfspeed one actually… that gave us the ability to switch super fast. That was the push on our side—we want to switch faster and see if that can give us efficiency, which it did. So we’ve gotten over and over and over during these inverter development cycles, switching faster and faster and faster,” he said.

At the time, few manufacturers looked at silicon carbide power electronics for road-going EVs. “Now everyone wants silicon carbide, and the reason they want it is the same reasons we do,” Charles said. “So the tech that we pushed then has really caught up now—the race to road is really clear. If I kind of map our switching speed increase, we’ve done five evolutions with different topologies of the in-house inverter. Now the road cars are coming along and the benefit there is range, ultimately; it means smaller batteries.”

A complaint that has been leveled at Formula E in the past is that the technical rules limit the amount of research and development that’s possible due to a high number of spec components like the chassis and battery. Indeed, this was cited as a reason by Audi and BMW to withdraw from the sport. But Charles sees it differently.

“It’s so crazy the technical freedom we have got. On the software side—completely free. On the motor and inverter—completely free, just a power limit. So we just could go completely bananas, and that’s the result that you get now. I’m talking with my Jaguar Land Rover colleagues all the time because they’re looking at us, going, “Wow, you did that. That’s really cool. How did you deal with that? What was the problem?” And it sounds silly, but all those lessons that we learned, all the mistakes we’ve made, are shortcuts for these guys,” he said.

An example of one of those lessons was the need to shield electronic components. “As you switch faster, the EMI that’s given off from those switching devices gets more and more and more, and you start turning off your other systems on the racecar,” Charles explained. “So we did lots of technical coatings in the first unit, very simple mechanical things to start with, where we tried to stop those components, the EMI getting outside of the inverter,” he continued.

Other lessons have involved drivability. “You’ve got such high capability to deliver torque so quickly, and the drivability that the drivers feel is very closely linked to how well you control now, so you can deliver [torque] instantly. It’s not like you’ve got to turn the engine to deliver more quickly, we’re delivering quickly already, but we got very accurate or very strong and quick capability to move the target,” Charles said.

https://arstechnica.com/?p=1901044