New fuel cell material can run efficiently in reverse, storing energy

Lithium batteries can readily smooth out short-term hiccups in the supply of intermittent renewable energy. But they’re not ideal for long-term storage, since they’ll slowly discharge. They also aren’t great for large quantities of energy—to store more, you keep having to buy more battery. Because of these issues, there has been research into a number of technologies that scale better, like flow batteries and renewable fuel production. But these pose their own challenges, both chemical and economic.

But researchers are now reporting a possible solution to some of these problems: a fuel cell that can be run efficiently in both directions, either using hydrogen or methane to produce electricity or using electricity to produce these fuels. Their measurements suggest that, after doing a complete cycle, they get out 75 percent of the electricity they put in to start with.

Limitations abound

Batteries, as we mentioned above, don’t work for longer-term storage, as they will typically lose charge slowly. They’re also expensive, as adding capacity means adding more batteries. Flow batteries solve some of these problems by storing the charged and discharged forms of a chemical in different tanks; larger or additional tanks are cheap, making expanded capacity relatively simple and inexpensive. But flow batteries aren’t as efficient as traditional batteries, and the chemicals they use can be toxic or corrosive.

An alternative for longer-term storage is to convert any excess electricity to fuel. But these reactions often have efficiency problems of their own, meaning some of the energy is lost in the process. And the costs can be quite large, since you typically need hardware for both fuel production and electricity generation, as well as very pure sources of water and expensive catalysts.

One option for cutting the costs is what’s called a reversible fuel cell. Fuel cells simply separate different parts of a chemical reaction so that the electrons that are transferred during the reaction can be used as a source of electricity. Operating in the forward direction, fuel cells will take hydrogen or methane as fuel and produce electricity by combining it with oxygen from the air. Operating in reverse, they’ll use electricity to drive the production of hydrogen starting with water, or methane if given water and CO2.

This allows for a completely reversible cycle by which electricity is essentially stored in the form of hydrogen or methane, without the need for separate hardware for storage and use. In essence, it acts like a big battery. Alternately, hydrogen and methane are valuable chemical stocks or can be used to power various forms of transport. Clearly, a reversible fuel cell is extremely flexible. So why aren’t we using them?

A number of types have been built, but they all have issues. Some forms require high temperatures to function. All of them produce a mixture of hydrogen and water that’s less valuable than pure, dry hydrogen. And the efficiency of the round-trip reaction is often dramatically lower than an actual battery could provide. In many cases, the catalysts required degrade rapidly.

A moderate solution

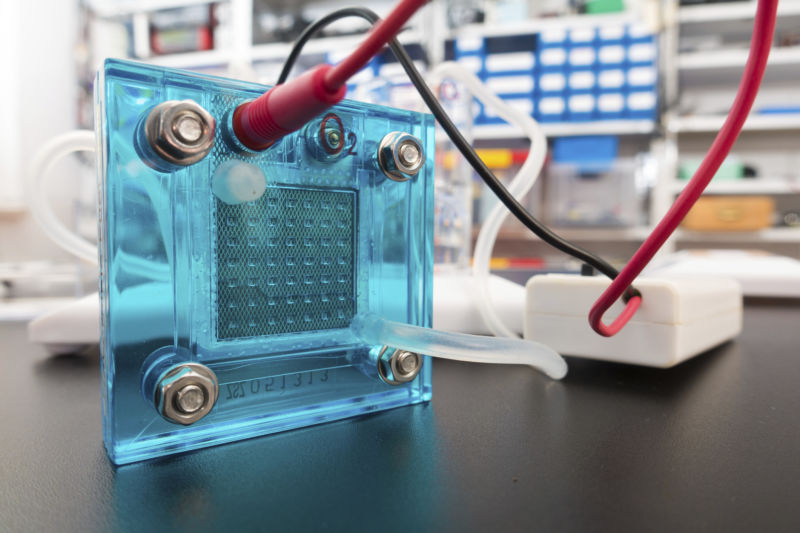

A group of researchers at the Colorado School of Mines decided to take a closer look at a technology called reversible protonic ceramic electrochemical cells (no, you won’t have to remember that). This technology has been very efficient when running in the forward direction and only requires what, for fuel cells, are moderate temperatures (400-600°C). That places them within the range where the operating temperature could be reached by using sources of waste heat from industrial processes or traditional power generation.

Unfortunately, they also lose more than 30 percent of the energy put in as electricity when they’re running in reverse. So, the research team performed some computer modeling to figure out where that energy was going, starting with a combination of Ba/Ce/Zr/Y/Yb and Ba/Co/Zr/Y electrodes. The modeling suggested that the current lost during operation is being carried off by holes, areas with a lower than normal number of electrons that can migrate around the material. They found that they could reduce hole formation by changing the electrolyte; once that was done, they started testing its performance.

These tests included finding the optimum current density in the hardware—too low, and the hydrogen doesn’t flow across the fuel cell; too high, and the system uses up all its water before more can diffuse in. The optimal operating temperature turned out to be roughly 500°C, at which point over 97% of the electricity being supplied ended up involved in driving the chemical reaction. Given water alone, the system would produce hydrogen; given water and carbon dioxide, it would produce methane.

Using the hydrogen reaction, the overall efficiency of the system—how much electricity you get out compared to what you put in—ended up being 75 percent. Not as good as batteries, but remember that this can scale up to however much hydrogen storage you can provide and can retain it indefinitely.

But the key thing may be the system’s stability. The researchers ran the reverse reaction for over 1,200 hours with no appreciable degradation of any of the critical materials. Imaging of those materials showed no apparent structural changes after all that use. Obviously, we’d want this to run for years, rather than 50 days, but the fact that it worked so well after 50 days of use suggests that there won’t be any unpleasant surprises in store.

All of this sounds extremely promising, but there are a large number of hurdles left to clear. Although there’s nothing like the platinum catalysts often used for splitting water, ytterbium still runs about $14,000 a kilogram, which could make scaling up the hardware rather pricey. Someone would also have to show that the hardware could scale, in terms of both manufacturing and functioning as a reversible fuel cell when surrounded by standard industrial parts, rather than hand-tuned lab equipment.

Finally, we currently don’t have an energy architecture in place to use or store large volumes of hydrogen or to funnel waste heat into hardware like this. So, there’s a lot of work left to do.

Nature Energy, 2019. DOI: 10.1038/s41560-019-0333-2 (About DOIs).

https://arstechnica.com/?p=1473709