Open source espresso machine is one delicious rabbit hole inside another

Making espresso at home involves a conundrum familiar to many activities: It can be great, cheap, or easy to figure out, but you can only pick, at most, two of those. You can spend an infinite amount of time and money tweaking and upgrading your gear, chasing shots that taste like the best café offerings, always wondering what else you could modify.

Or you could do what Norm Sohl did and build a highly configurable machine out of open source hardware plans and the thermal guts of an Espresso Gaggia. Here’s what Sohl did, and some further responses from the retired programmer and technical writer, now that his project has circulated in both open hardware and espresso-head circles.

Like many home espresso enthusiasts, Sohl had seen that his preferred machine, the Gaggia Classic Pro, could be modified in several ways, including adding a proportional–integral–derivative (PID) controller and other modifications to better control temperature, pressure, and shot volumes. Most intriguing to Sohl was Gaggiuino, a project that adds those things with the help of an Arduino Nano or STM32 Blackpill, a good deal of electrical work, and open software.

It looked neat to Sohl, but, as he told Ars in an email, he was pretty happy with the espresso he had dialed in on his Classic Pro. “[S]o I decided to build a new machine to experiment with. I didn’t want to risk not having coffee while experimenting on a new machine.” Luckily, he had an older machine, an Espresso Gaggia, and Gaggia’s home espresso machine designs have been fairly consistent for decades. After descaling the boiler, he had a pump, a boiler, and, as he writes, “a platform for experimentation, to try out some of the crazy things I was seeing on YouTube and online.”

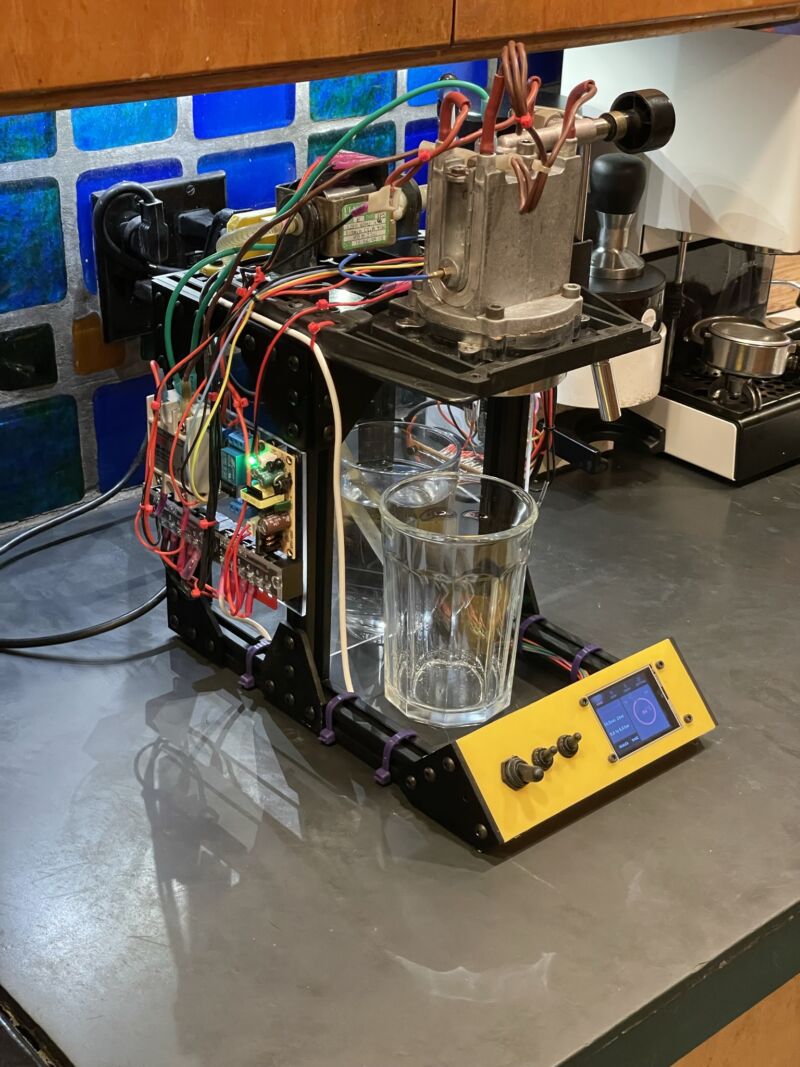

Sohl ended up creating a loose guide to making your own highly configurable machine out of common espresso machine parts and the Gaggiuino software. From his own machine, he salvaged a pump with a pressure sensor, a boiler with a temperature sensor, an overpressure valve, and brew head. Sohl made a chassis for his new machine out of extrusion rails and stiffening plates.

The high-voltage boards and components were assembled breadboard style onto acrylic panels, held up by poster-tack adhesive. A 120-volt power connector was salvaged from a PC power supply, then mounted with a 3D-printed bracket. The low-voltage wires and parts were also tacked onto acrylic, individually crimped, and heat shrink-wrapped. And the control panel was 3D-printed, allowing for toggle switches and a touch-panel screen.

There’s more work to be done on Sohl’s unit; the exposed boiler and 120-volt wiring need to be hidden, and a drip tray would be nice. But it works. The first shot was fast and under-extracted, suggesting a finer grind and settings changes. Then again, that describes almost every first-time home espresso setup. Sohl writes that he hopes future versions of his project will make use of the Gaggiuino project’s own circuit board design and that he’ll have his 3D project files posted for sharing.

In an email interview, Sohl wrote that he has received friendly and encouraging responses to his project.

Mostly people are plotting their own path and wondering how deep they want to get into the weeds with extra control. My advice (if they ask!) is to get an ok machine and grinder (The Gaggia Classic and perhaps the Baratza Encore ESP grinder work for me) and then spend some quality time getting to know how to use them. For example, my grinder is old and it took me forever to figure out how fine I really had to go to get the kind of espresso I wanted.

Asked if he was intimidated by the amount of control he now had over each shot, Sohl responded, “Yes, but that’s a good thing?”

The level of control is amazing, and I am only beginning to dial in a shot that is as good as the one I get every morning from my stock machine. The machine itself still needs work before it goes into daily use – I want to add a decent drip tray before it will be really practical, and digital scales are another thing I… want to try. Honestly I think it may be overkill for my espresso needs, but I really enjoy the detailed work that goes into building and learning to use something like this. I think the satisfaction I get from building and experimenting is probably as important as the end product.

I asked Sohl which aspect was the most difficult: hardware, software/firmware, or getting the espresso dialed in. “It’s all pretty complicated, hard to pick just one thing,” he wrote. The software flashing worked without any programming on his part. The hardware required new skills, like crimping connectors, but he went slow and learned from small mistakes. Getting the espresso dialed in will probably be hardest, Sohl wrote. “I think I’ll buy a bag of fresh dark roast and spend a couple of afternoons pulling shots and changing parameters.”

Overall, “This is one of the most satisfying builds I’ve done—the mix of mechanical work, electronics, water and steam are challenging,” Sohl wrote. You can see many more shots of the DIY machine and its details at Sohl’s Substack, which we first saw via the Hackaday blog.

https://arstechnica.com/?p=1927022