This is GM’s new series of Ultium Drive electric motors

-

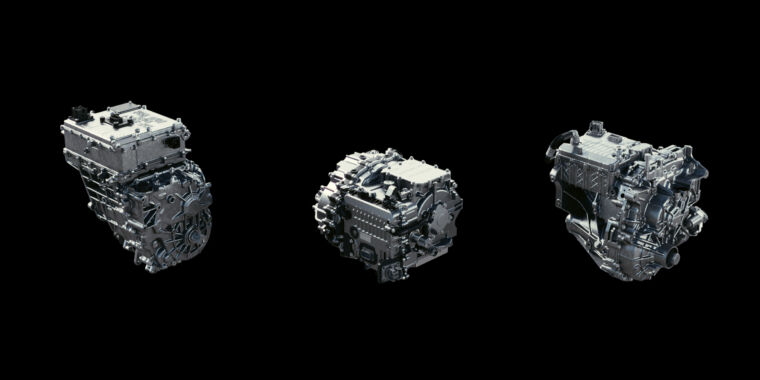

This is GM’s new family of Ultium Drive electric vehicle drive units. From L-R: Assist all-wheel drive unit, front-wheel drive unit, rear wheel drive unit, front- or rear-wheel truck drive unit, dual motor truck drive unit.General Motors

-

A closer look at the rear-wheel drive unit. Like the others, it combines the electric motor along with its power electronics into a compact package.Steve Fecht for General Motors

-

GM has designed three electric motors that can be combined in a variety of ways to create front-wheel drive, rear-wheel drive, or all-wheel drive vehicles with varying levels of power and torque.Steve Fecht for General Motors

-

An electric motor stator is assembled by hand during pre-production at General Motors Global Propulsion Systems Center in Pontiac, Michigan.Jeffrey Sauger for General Motors

-

GM’s wireless battery management system is expected to drive the company’s Ultium-powered EVs to market faster, as time won’t be needed to develop specific communications systems or redesign complex wiring schemes for each new vehicle. The wBMS helps to ensure the scalability of Ultium batteries across GM’s future lineup, encompassing different brands and vehicle segments.Jeffrey Sauger for General Motors

It might be too early to say that the auto industry is undergoing a great electrification. But more and more automakers are headed in that direction as product pipelines swell, with new battery-electric vehicles arriving over the next few years. Take General Motors—it plans to bring 22 new BEVs to market between now and 2023, starting with a reborn GMC Hummer to be debuted later this September. To make matters simpler, GM is standardizing the components it will use to build what promises to be a wide variety of vehicles.

We already learned a little about GM’s modular Ultium battery packs, which it claims will break the $100/kWh barrier “early in the platform’s life.” As the reveal of the Hummer approaches, the company is opening up about other aspects of its new BEV brigade. And this week it was time for motors to take to the stage. GM has developed a new family of modular drive units called Ultium Drive that it will mix and match in cars, crossovers, SUVs, and trucks.

In total, there are five drive units, each of which integrates the power electronics as well as the electric motors. There are drive units for front-wheel drive, rear-wheel drive, and an assist all-wheel drive unit, and then a pair of drive units for trucks. One of these can be used for the front or rear axle, while the other is a dual motor drive unit for rear axles. And inside each drive unit is one of three electric motors in the Ultium Drive family: a permanent magnet primary front-wheel drive motor, a permanent magnet primary drive motor that’s happy in either front- or rear-wheel drive configurations, and a smaller induction magnet assist motor.

“We went with a modular strategy, so there are three motors inside of these drive units that scale—they look like siblings and interchange a lot of parts—and then the drive units themselves also interchange a lot of parts. They have common manufacturing locators so multiple different types of drive units can run down the same manufacturing line. And because they share parts, and because they’re flexible, we can really leverage our scale: we can adjust different types of drive units by vehicle mix; we can source components at really high volumes, and we can vertically integrate much more of the drive units than we had before,” explained Adam Kwiatkowski, GM’s executive chief engineer of electric vehicles.

GM is still being coy about power and torque outputs for the motors. We know that the GMC Hummer will use three motors in total (a front truck drive unit and the dual-motor truck drive unit, at a guess) with a combined output of 745kW (1,000hp). Kwiatkowski wouldn’t be drawn more on the specs other than to tell me that both power and torque density (i.e. the amount of power or torque divided by the volume of the motor) will be industry leading.

Kwiatkowski told me that the process of developing a new family of electric motors wasn’t all that different to designing a new internal combustion engine, something that occupied him for the first 15 years of his career. “A lot of the same tenets and ideas are completely fungible in the electric propulsion space. So things like interchangeability, common datums and manufacturing locators; things that allow us to scale and vertically integrate those concepts are just part of our propulsion design DNA at GM,” he told me.

Then again, GM has a bit of experience with electric motor design, too, thanks to the Volt, Bolt, and EV1. As you might expect, the main focus for this third generation of electric motors has been efficiency. “We want every single joule of electric energy that goes into the motor to propel the wheels. So we were really focused on reducing losses inside of the unit, whether it be i2r losses or magnetic losses or switching losses,” he said.

Listing image by General Motors

https://arstechnica.com/?p=1707354