Throw out all those black boxes and say hello to the software-defined car

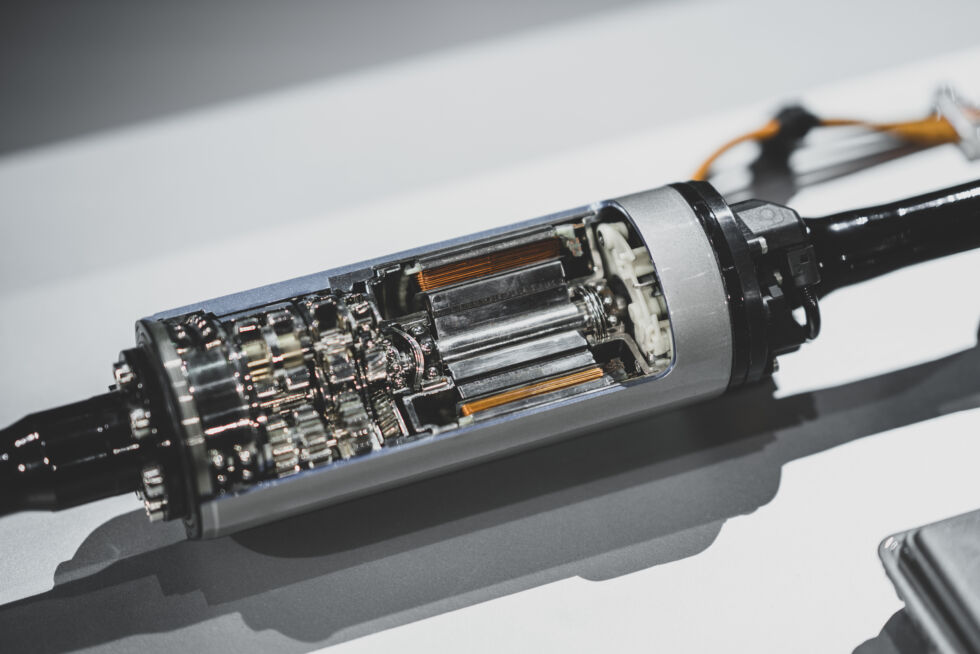

One of the auto industry trends I’m most excited about these days is the move to clean-sheet designs for car platforms and architectures. For decades, features have accumulated like cruft in new vehicles: a box here to control the antilock brakes, a module there to run the cruise control radar, and so on. Now engineers and designers are rationalizing the way they go about building new models, taking advantage of much more powerful hardware to consolidate all those discrete functions into a small number of domain controllers.

The behavior of new cars is increasingly defined by software, too. This is merely the progression of a trend that began at the end of the 1970s with the introduction of the first electronic engine control units; today, code controls a car’s engine and transmission (or its electric motors and battery pack), the steering, brakes, suspension, interior and exterior lighting, and more, depending on how new (and how expensive) it is. And those systems are being leveraged for convenience or safety features like adaptive cruise control, lane keeping, remote parking, and so on.

Of course, this only works if that software is any good. “There is absolutely no question that software has been treated like a stepchild—I always say the fifth wheel in the car. So like a necessity, but not something that has been managed with care,” said Maria Anhalt, CEO of the automotive supplier Elektrobit, which develops digital systems and software for OEMs.

“But what we also see is that every OEM and every SOP and every product line starts from scratch in procurement and doing things for the first time. So part of the complexity is doing things multiple times and not thinking of reuse and architecture and modularity and upgradability,” Anhalt explained.

Domain-controlled architecture

One can certainly see the appeal of a clean-sheet design that leverages modern computing to simplify a car’s underlying design.

“It is much more elegant,” said Oliver Hoffmann, Audi’s board member in charge of technology development. That doesn’t make it easy, though. “But to be honest, it is challenging, because all those functions which were located all over the car—a lot more than 200 controllers—you have to bring all those functions into the domain controller. But it is a very smart solution,” he said.

“So as an example we have what we call the high compute platform, and we have a dedicated domain for infotainment, and we are able to update but also to upgrade, so that every year or every two years you can bring an upgrade in terms of hardware, and we are able to run over-the-air updates,” Hoffmann told me.

The first Audi we’ll see adopt this approach is next year’s Q6 e-tron, an electric SUV that is one of the first EVs to use Volkswagen Group’s new PPE (Premium Platform Electric) architecture, which will also be used to create the A6 e-tron and the next Porsche Macan.

All the domains—which include driving behavior, thermodynamics, and energy management as well as infotainment—are upgradeable over the air; some earlier implementations of OTA updates by automakers have only allowed for certain systems in those vehicles (like infotainment, but not the powertrain) to be easily updated. “So [it’s] a very, very big advantage with this kind of platform, and it’s a smart solution,” he said.

I was curious if the move from tens or hundreds of discrete black boxes meant completely rewriting all those functions from scratch. While that’s always an option, Hoffmann said that Audi was able to use its experience to make the job a little easier. But for PPE that still meant a new way of working.

“It was a completely new way to work together with suppliers,” Hoffmann said. “So in the past you had a supplier responsible for the ABS, which was a separate and dedicated controller. Now, there’s an interaction between all these domain controllers, so you have to double-check if all this works together with all these other domains or with the rest of the software in the main controller, which makes it very complex,” he explained. The solution was to organize “supplier parties” to bring everyone together. This was also complicated, Hoffmann told me, “but I think it is the new way for a collaboration model,” he said.

https://arstechnica.com/?p=1943172