Watch this paper doll do sit-ups thanks to new kind of “artificial muscle”

A new twist on lightweight organic materials shows promise for artificial-muscle applications. Chinese scientists spiked a crystalline organic material with a polymer to make it more flexible. They reported their findings in a new paper in ACS Central Science, demonstrating proof of concept by using their material to make an aluminum foil paper doll do sit-ups.

There’s a lot of active research on developing better artificial muscles—manmade materials, actuators, or similar devices that mimic the contraction, expansion, and rotation (torque) characteristic of the movement of natural muscle. And small wonder, since they could be useful in a dizzying range of potential applications: robots, prosthetic limbs, powered exoskeletons, toys, wearable electronics, haptic interfaces, vehicles, and miniature medical devices, to name just a few. Most artificial muscles are designed to respond to electric fields, (such as electroactive polymers), changes in temperature (such as shape-memory alloys and fishing line), and changes in air pressure via pneumatics.

Yet artificial muscles typically weigh more than scientists would like and don’t respond as quickly as needed for key applications. So scientists are keen to develop new types of artificial muscle that are lightweight and highly responsive. Just this past week, Science featured three papers from different research groups (at MIT, University of Texas at Dallas, and University of Bordeaux) describing three artificial-muscle technologies based on tiny twisted fibers that can store and release energy.

The Chinese scientists built their version of an artificial muscle out of a special class of materials known as covalent organic frameworks (COFs), first synthesized in 2005. To make COFs, scientists link up certain carbon-containing molecules (boric acid, for example) via covalent bonds (in which atoms share electron pairs) into a porous crystalline powder. That crystalline structure imparts mechanical properties that are useful for catalysis, gas storage, and drug delivery, for example. But a standard COF is too brittle to fashion into sheets or membranes, which would open a whole new swathe of practical applications.

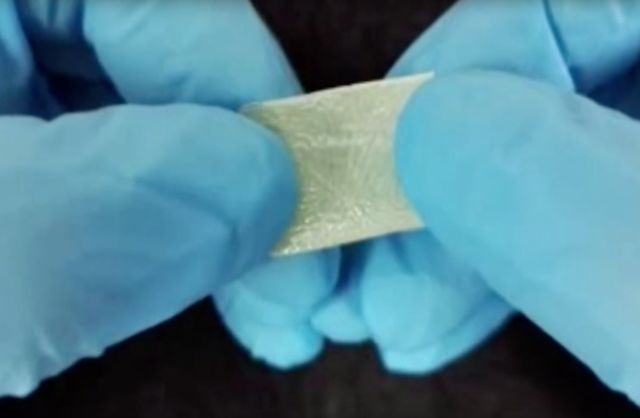

The Chinese scientists added polyethylene glycol into the reactant mix when building their COF compound, which effectively bridged the porous spaces to create a version that was much more compact and flexible. A membrane made of this polymer covalent organic framework (polyCOF) can be bent, twisted, and stretched repeatedly. The team also noticed that, when exposed to certain chemical vapors, the membrane would curl up, then uncurl as soon as it was no longer in contact with the vapor. Those two properties make polyCOFs a promising candidate for future artificial-muscle applications.

As proof of concept, the Chinese researchers used a membrane as the waist of a paper doll they fashioned out of aluminum foil. Then they exposed the doll to ethanol vapors. The membrane contracted in response, causing the doll to sit up. The membrane relaxed when the vapor was no longer present, and the doll sat back down. The researchers were able to repeat this process several times. They surmise that the polyCOF pores expand upon binding with molecules in the gas, and this is what’s causing the contraction.

DOI: ACS Central Science, 2019. 10.1021/acscentsci.9b00212 (About DOIs).

Listing image by YouTube/American Chemical Society

https://arstechnica.com/?p=1538365