There’s a classic 2009 Mythbusters episode in which the hosts demonstrate how someone could wet their hand and dip it ever so briefly into molten lead without injury. The protective mechanism is known as the “Leidenfrost effect,” and it could one day prove useful for microfluidic devices, particularly in microgravity environments, among other applications. We’re one step closer to achieving those applications, thanks to new insights into the phenomenon uncovered by MIT scientists. They described their findings in a recent paper published in the journal Physical Review Letters.

As we’ve reported previously, the Leidenfrost effect dates back to 1756. That’s when German scientist Johann Gottlob Leidenfrost observed that, while water splashed onto a very hot pan sizzles and evaporates very quickly, something changes when the pan’s temperature is well above water’s boiling point. When that happens, Leidenfrost discovered, “gleaming drops resembling quicksilver” will form and will skitter across the surface.

In the ensuing 250 years, physicists came up with a viable explanation for why this occurs. If the surface is at least 400 degrees Fahrenheit (well above the boiling point of water), cushions of water vapor, or steam, form underneath the droplets, keeping them levitated. The droplet can skitter across the surface with very little friction. The Leidenfrost effect also works with other liquids, including oils and alcohol, but the temperature at which it manifests (the “Leidenfrost point”) will be different.

Physicists are still learning more about this effect over two centuries later. For instance, French physicists in 2018 discovered that the drops aren’t just riding along on a cushion of steam; as long as they are not too big, they also propel themselves. An imbalance in the fluid flow inside the Leidenfrost drops, acts like a small internal motor. As the drops evaporated, becoming smaller and more spherical, they began to roll like a wheel (aka the “Leidenfrost wheel“).

And in 2019, an international team of scientists finally identified the source of the accompanying cracking sound Leidenfrost reported. The scientists found that it depends on the size of the droplet. Smaller drops will skitter off the surface and evaporate, while larger drops explode with that telltale crack. The culprit is particle contaminants, present in almost any liquid. Larger drops will start out with a higher concentration of contaminants, and that concentration increases as the droplets shrink. They end up with such a high concentration that the particles slowly form a kind of shell around the droplet. That shell interferes with the vapor cushion holding the drop aloft, and it explodes when it hits the surface.

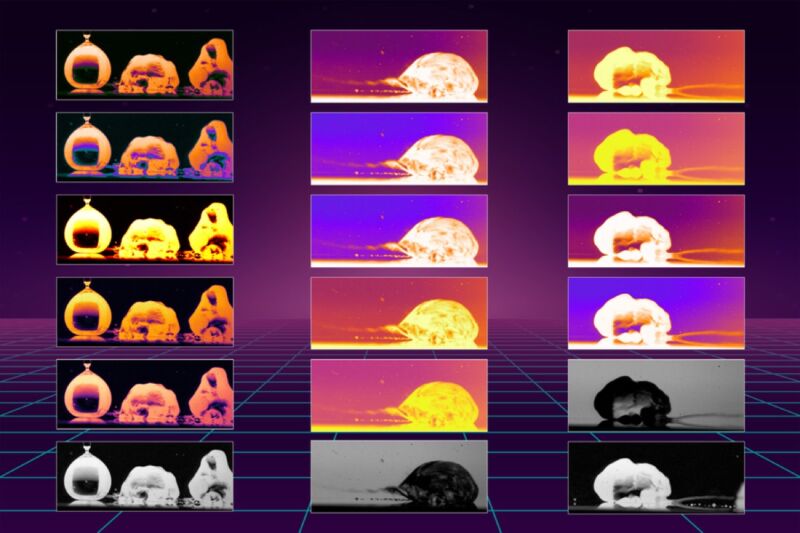

The co-authors of this most recent paper (MIT mechanical engineer Kripa Varanasi and his graduate student Victor Julio Leon) are interested in harnessing the Leidenfrost effect for practical applications. They conducted a series of experiments that involved dropping millimeter-sized water droplets onto hot solid surfaces—silicon wafers between 10 to 100 microns thick—covered in thin films of different kinds of oil and filming what happened with high-speed cameras.

They expected that Leidenfrost droplets would move more slowly on a surface coated with oil, because oil is roughly 100 times more viscous than air and thus would produce more friction than a vapor film. But when the researchers analyzed the footage, they found the opposite occurred: Leidenfrost droplets skittered along much more rapidly in random directions on oil-coated surfaces than on plain metal surfaces.

“We were stumped at multiple levels as to what was going on, because the effect was so unexpected,” said Varanasi. “It’s a fairly complex answer to what may look seemingly simple, but it really creates this fast propulsion.” Further study showed that, under the right conditions, a thin coating formed outside each droplet, like a cloak. As the droplet got hotter, minuscule bubbles of water vapor began to form between the droplet and the oil, then moved away. Subsequent bubbles typically formed near the same spots, forming a single vapor trail that served to push the droplet in a preferred direction.

Tiny bubbles

The formation of the tiny bubbles also occurs much more rapidly than the transfer of heat though the oily film. The resulting asymmetry means less friction under the bubble, rapidly propelling it off the hot oily surface. Varanasi drew an analogy between the oily film, or cloaking effect, and the rubber of a balloon. The force of the vapor bubbles bursting causes the “balloon” to fly away, “because the air is going out one side, creating a momentum transfer,” he said.

Among the potential applications would be microrobots, de-icing systems, and self-cleaning surfaces that remove contaminants like salt to avoid damage from buildup. Until now, such propulsion methods for water droplets were limited to just a few millimeters per second. But the droplets in Varanasi’s and Leon’s experiments moved much more quickly: about 10 cm/s.

Several different factors can affect the direction of self-propulsion, such as the size of the droplets, the thickness and viscosity of the oily films, and the surface texture and thermal conductivity. So the authors admit that they cannot yet precisely control that direction. However, “Further studies on the formation of the initial asymmetry and the rich oil-droplet cloaking dynamics may shed light on how to control the Leidenfrost point on thin liquid films and the self-propulsion direction on a surface,” they concluded. “Such a surface could quickly and controllably shed corrosive and fouling droplets from heated surfaces.”

DOI: Physical Review Letters, 2021. 0.1103/PhysRevLett.127.074502 (About DOIs).

https://arstechnica.com/?p=1787403