The human fingertip is an exquisitely sensitive instrument for perceiving objects in our environment via the sense of touch. A team of Chinese scientists has mimicked the underlying perceptual mechanism to create a bionic finger with an integrated tactile feedback system capable of poking at complex objects to map out details below the surface layer, according to a recent paper published in the journal Cell Reports Physical Science.

“We were inspired by human fingers, which have the most sensitive tactile perception that we know of,” said co-author Jianyi Luo of Wuyi University. “For example, when we touch our own bodies with our fingers, we can sense not only the texture of our skin, but also the outline of the bone beneath it. This tactile technology opens up a non-optical way for the nondestructive testing of the human body and flexible electronics.”

According to the authors, previously developed artificial tactile sensors could only recognize and discriminate between external shapes, surface textures, and hardness. But they aren’t capable of sensing subsurface information about those materials. This usually requires optical technologies, such as CT scanning, PET scans, ultrasonic tomography (which scans the exterior of a material to reconstruct an image of its internal structure), or MRIs, for example. But all of these methods also have drawbacks. Similarly, optical profilometry is often used to measure the surface’s profile and finish, but it only works on transparent materials.

When we touch something with our fingers, the skin experiences mechanical deformation such as compression or stretching, which triggers mechanoreceptors to send out electrical impulses. These impulses travel through the central nervous system to the brain’s somatosensory cortex. The brain integrates those electrical impulses to identify the features of the object that we touch. That tactile feedback enables us to recognize a material’s shape, surface texture, and stiffness or softness.

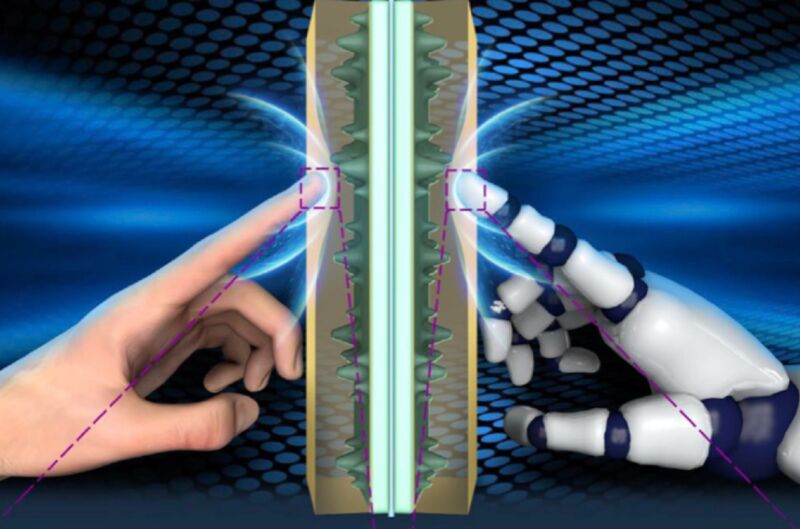

The smart bionic finger mimics this feedback system. A metallic cylinder mounted on top of the finger serves as the contact tip, while carbon-fiber beams serve as tactile mechanoreceptors (the sensing unit). These are connected to a signal-processing module. The finger “scans” the target object’s surface by periodically applying pressure, akin to a poke or a prod. This compresses the carbon fibers, and how much the material compresses conveys information about its relative stiffness or softness. That information, along with where on the surface it was recorded, is then sent to a computer, which translates the data into a 3D map.

The authors put their bionic finger to the test using different complex objects. For instance, they tested the finger’s ability to detect and map out a rigid letter “A” just beneath a soft silicon layer (see video above), along with other abstract shapes. The fingers could even tell the difference between rigid and soft internal materials and the soft outer silicone coating.

They also created a 3D-printed physical model for human tissue out of three layers of hard polymer (for the “skeleton”) and a soft silicone outer layer (for the “muscles”). The bionic finger scanned and successfully reproduced a 3D profile of the model tissue’s structure, including the location of a “blood vessel” located underneath the “muscle” layer.

Finally, the authors tested the bionic finger on a defective electronic device, successfully creating a map of the internal components. The finger could pinpoint where the circuit had been disconnected and identified a hole that had been improperly drilled without breaking through the surrounding outer layer. “Next, we want to develop the bionic finger’s capacity for omnidirectional detection with different surface materials,” said Luo.

DOI: Cell Reports Physical Science, 2023. 10.1016/j.xcrp.2023.101257 (About DOIs).

https://arstechnica.com/?p=1918825