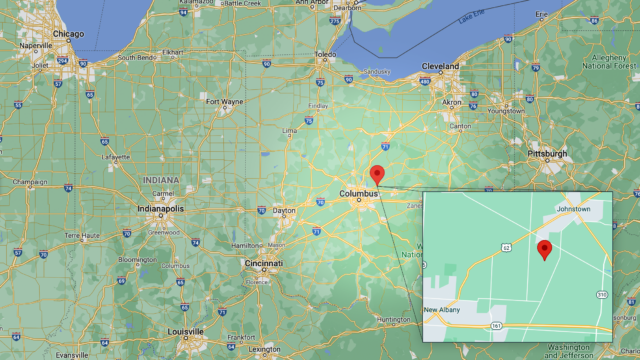

Intel announced the location of its megafab today, a 1,000-acre parcel on the outskirts of the Columbus, Ohio, metro area. The semiconductor manufacturer plans to break ground on two leading-edge fabs by the end of the year and enter production in 2025.

“This is all part of the strategy that our CEO Pat Gelsinger announced back in March,” Intel Senior Vice President Keyvan Esfarjani told Ars.

“We are starting with two fabs, and that’s all in line with the growing demand for what the industry needs,” he said. “It’s also critically important for the balance of the supply chain around the world.”

Though the company will start with two fabs, the massive site gives Intel “optionality,” said Esfarjani, who oversees manufacturing, supply chain, and operations for the company worldwide. There’s room for up to eight fabs, “but we have space to do even more,” he said. If the entire site gets built out, Intel could spend as much as $100 billion on the Ohio site alone.

Esfarjani said that Intel spent about nine months evaluating 35–40 locations across the US before settling on the New Albany parcel. The scale of the project demanded an entirely new site, he said. “All of our sites within the company, whether it’s in Oregon, New Mexico, or Arizona—we are essentially at the level where it’s not going to have enough footprint, enough space where you want to grow for those mega scales.”

Gelsinger is betting that Intel can regain the lead in semiconductor manufacturing by making not just its own chips but chips for other companies, too. Traditionally, Intel has designed and manufactured chips for itself, but the success of foundries like TSMC, which focuses on making chips for others, has pushed Intel to open its fabs. In theory, making more chips will allow Intel to master new processes faster while giving it more cash to invest in the research and development of more advanced nodes. The new Ohio site will give Intel significant new manufacturing capacity, which Esfarjani said would be available to foundry customers, depending on demand.

While the company considered hundreds of variables, a few key factors helped influence the decision. First, Intel needed a location with the resources to support facilities of this size. The company required somewhere with ample land, water, and power. Second, it needed a metro area that could help supply enough technicians and engineers to run the fabs. And lastly, Intel was looking for state and local governments that would be eager to welcome the sites. (Amazon’s recent struggles with its HQ2 no doubt crossed Intel executives’ minds.)

“Out of all the options, Ohio—no brainer. It came to the top,” Esfarjani said. The farm fields around Columbus provided space to build and expand, while the region’s temperate climate offers a steady supply of water. (Esfarjani pointed out that the company recycles 95 percent of its water.) The state is also among the nation’s top 10 electricity producers, though nearly all of the power is generated by burning natural gas and coal. Intel intends for the site to be run on 100 percent renewable power, which will require the state to add significant wind and solar installations. “Part of why we are so anxious to move forward in announcing this project is so that we can formalize those engagements and get those agreements under way,” Esfarjani said.

Intel will also be working with The Ohio State University and nearby community colleges to ensure a steady supply of technicians and engineers. Though the company isn’t releasing details of its educational plans yet, it did say it will spend $100 million supporting educational institutions, students, and the NSF to develop a pipeline for semiconductor jobs.

https://arstechnica.com/?p=1827473