Carbon capture. Hydrogen production. Synthetic fuels. All of these technologies have been proposed as potential resources for dealing with the crises created by our carbon dioxide emissions. While they have worked in small pilot demonstrations, most of them haven’t demonstrated that they can scale to provide the economical solutions we need.

In the meantime, a group of European researchers sees the methods as part of a single coherent production platform, one that goes from sunlight and air to kerosene. Thanks to a small installation on the roof of a lab in Zurich, the team has been producing small amounts of different fuels using some mirrors and a handful of reaction chambers. While the full production process would also need to demonstrate that it can scale, the researchers calculate that the platform could fuel the entire commercial aircraft industry using a small fraction of the land in the Sahara.

The process

There are only three steps involved in the process of turning air into fuels. The first is separating out the raw ingredients, specifically carbon dioxide and water. This is done using a small commercial unit from a spinoff of ETH Zurich; the device uses a heating/cooling cycle and amines that absorb both CO2 and H2O at environmental temperatures, releasing them when they are heated. Critically, the supplied water is highly pure and doesn’t compete with the many other uses we have for clean water.

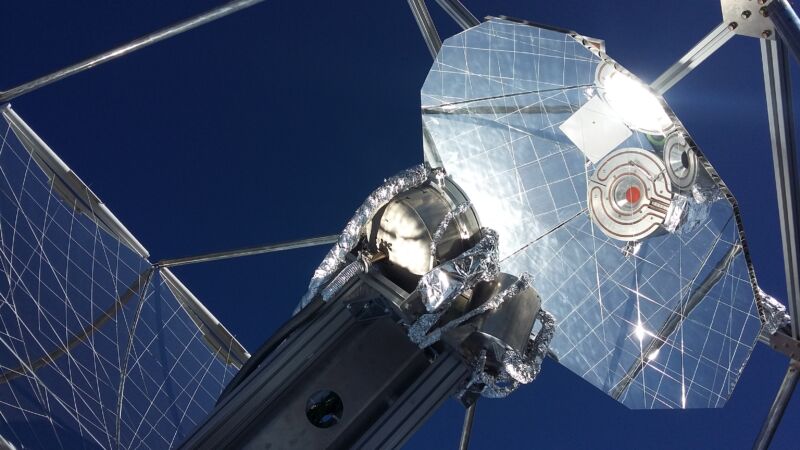

From there, the materials are sent to another unit that converts them to carbon monoxide and hydrogen, again using a heating/cooling cycle. The process uses cerium oxide, which partially decomposes and releases oxygen at high temperatures. Upon returning to environmental temperatures, the cerium will strip oxygen from whatever source (water or carbon dioxide) happens to be present. The high heat needed to drive this process is provided by a set of mirrors that concentrate incoming sunlight, with the reaction chamber peaking at over 5,000 suns while heating. The heating is sufficient to run two of these reaction chambers at the same time—one for water and one for carbon dioxide—by switching the mirrors’ focus back and forth.

The resulting carbon monoxide and hydrogen are sent to a second reaction chamber, where a commercial copper-based catalyst can convert them to fuels like methanol or kerosene, with the reaction product being determined by the precise mix of materials put in place. This step requires high pressures and elevated temperatures.

The system is not entirely self-contained. Valves need opening and closing, and gasses need to be pressurized. But it would be relatively trivial to attach a photovoltaic panel and battery to handle these tasks. The heat used for the first and final steps could also be provided through the extraction of waste heat from the high temperatures used during the middle step.

At the very small scales used here, the process was pretty slow. Over the course of a day, with seven hours of useful sunlight, the setup produced 32 milliliters of methanol, which was mixed in with water as a major contaminant. Switching the reaction mix allowed for the production of kerosene, which is much easier to separate. Compared to the contaminants present in kerosene derived from fossil fuels, the results here were good. The synthetic kerosene lacked the sulfur- and nitrogen-containing chemicals that tend to result in soot and other pollutants.

Will it scale?

Overall, the results are clear: The process can work, but it’s not productive enough to matter in its current state, so a large portion of the paper considers optimization and scale. Optimization is mostly a matter of many little improvements, like the better use of waste heat to ensure all the necessary heat is provided by the solar reflectors. Other targets include better catalysts and more efficient means of storing the gasses between steps.

Then there’s a matter of scale. To fuel a daily round-trip flight between New York City and London, the researchers estimate, it would take 10 mirror farms directing sunlight at reaction chambers in an area that gets strong and consistent sunlight. That translates to covering around 3.8 square kilometers of the desert with mirrors. (For context, that’s about a quarter of the size of California’s Ivanpah solar facility.)

Providing for all of commercial aviation’s fuel needs would require taking over half of one percent of the surface of the Sahara Desert. And that means a lot of mirrors.

The researchers suggest we will likely see the sort of dramatic cost reductions seen in other renewable resources, including technologies like concentrating solar power. That mirror-based tech saw prices drop by 60 percent over a recent 15-year period. But it’s questionable whether the sorts of price drops we’ve seen with photovoltaics are possible, given the large material costs of all those mirrors and their associated hardware, plus the maintenance costs of keeping them clean.

The flipside is that concentrating solar power costs have continued to come down, and a lot of those savings could probably be applied to heat-driven chemistry like this. And it’s possible that this basic concept—solar-powered green chemistry—could be adapted to produce fuels with a higher value than kerosene.

Nature, 2021. DOI: 10.1038/s41586-021-04174-y (About DOIs).

https://arstechnica.com/?p=1810057