The most interesting thing we saw at the Consumer Electronics Show this year was the back side of Delta Airlines’ exhibit, where some Sarcos Robotics folks were putting the Guardian XO—a powered industrial exoskeleton—through its paces, and the adventurous (and patient) could wait for half an hour or so in line to operate one disembodied arm of the Guardian attached to a 50-pound suitcase.

-

We took this photo of an operator demonstrating movement and work in the Guardian XO at the Delta exhibit at CES.Jim Salter

-

This is the Guardian XO on its base station, at the Delta exhibit at CES 2020.Jim Salter

-

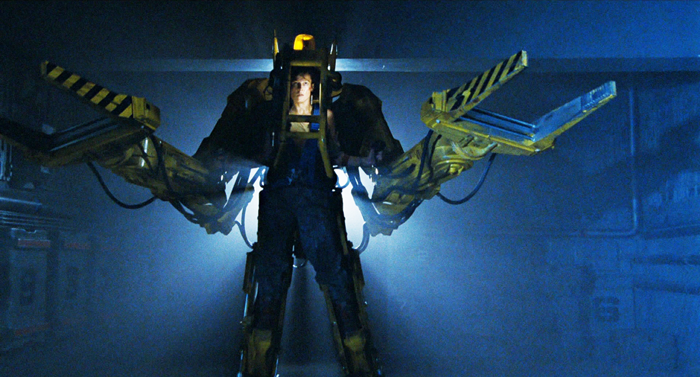

This stock photo of an operator walking in a Guardian XO does not omit any tethers; the exoskeleton is capable of free and easy movement.

Unfortunately, neither Sarcos nor Delta was about to let any journalists inside an actual Guardian XO. They had good reason, though—which became abundantly clear after we took a test run with a disembodied, statically mounted Guardian XO right arm. The suits aren’t just designed to be incredibly strong—they’re also designed for long-term, ergonomically correct operation that won’t destroy backs and knees the way a career in the military or heavy industry tends to. That’s great if you’re a trained professional trying not to injure yourself—not so great if you’re a random enthusiast suddenly given 20:1 muscular amplification in a densely packed crowd of thousands.

That term—20:1 muscular amplification—is a little misleading. The Guardian XO isn’t really 20 times as strong as a construction worker. The promotional materials we’ve seen rate the exosuit for weights that aren’t out of the question for a very strong human—200lbs total, 100lbs per arm, 50lbs per arm at full extension—but inside the Guardian XO, you’re handling those weights while working no harder than you might in a light office environment.

A strong person can lift the 50-pound weight attached to the robotic arm in the above video without much problem—but a one-armed front raise (the beginning of the motion actually being performed in the video) is out of the question. The real utility of the device isn’t only measured by how much it can lift, but how it becomes possible to hold those heavy weights very precisely, for long periods of time, in what would otherwise be awkward positions.

With such an exoskeleton, one worker might lift a 100- or 200-pound length of steel up to head height, while another does a tack weld on the underside. Or an exoskeleton-equipped worker might lift a pair of 70-pound pipe segments and carefully thread the bolts from one flange into the bolt holes in the next. More importantly, skilled workers should be able to do this kind of heavy work for entire 40-year careers—instead of retiring with blown-out backs and knees after 20 years or less.

According to Sarcos Robotics reps we spoke to at the show, the Guardian XO is capable of running for eight hours of heavy industrial work on a charge, and its batteries can be hot-swapped. The XO is entirely battery-powered, with no tether to limit the range or motion of the operator, who can walk forward, backward, or even sideways while operating the device. It’s quiet, too—in sharp contrast to the Boston Dynamics LS3 robotic pack mule, which can reportedly be heard coming a mile away.

Sarcos Robotics representatives told us that—at least for now—the XO isn’t really sold outright. Instead, it’s being long-term leased to customers like Delta. The lease terms include Sarcos Robotics employees to do employee training, as well as ongoing maintenance and inspection of the exoskeletons themselves.

https://arstechnica.com/?p=1647259