SCOTTSDALE, Arizona—The Nikola Motor Company wants to reinvent trucking by replacing diesel heavy-duty trucks with hydrogen fuel cell trucks. But hydrogen skeptics are numerous, and not without good reason. Although hydrogen fuel cell vehicles are quiet, emissions-free (with the exception of water) during operation, and relatively fast-charging compared to battery electric vehicles, they have a host of other problems.

First, hydrogen is hard to store, and it must be cooled and compressed. It’s also hard to transport. Additionally, H2 is not a green fuel in the US, for the most part. Generally, natural gas (CH4) is reformed to create H2 in ways that still cause carbon emissions. There is a way to create hydrogen fuel without the carbon emissions: by applying electricity to water (a process called water electrolysis). But water electrolysis has been prohibitively expensive, and if hydrogen can’t compete with diesel, what’s Nikola’s value proposition to freight companies that will make them want to switch?

This week, the company hoped to address those concerns during a two-day conference in Arizona. And in a 45-minute talk, Nikola’s vice president of hydrogen technology, Jesse Schneider, joined Jon André Løkke, the CEO of Norwegian water electrolysis company Nel Hydrogen, to outline Nikola’s plans to fuel hundreds or thousands of hydrogen fuel cell trucks per day.

Making the hydrogen

Nikola’s early partnership with Nel Hydrogen is a positive sign. Nel has been around for 90 years, supplying water electrolysis machinery to industrial and commercial companies in Europe. Løkke told Ars that the company has never made hydrogen from methane; water electrolysis is its primary business. Though the company has primarily built systems for industrial use, it sees its partnership with Nikola as a valuable way to expand its market into transportation, building the many refueling stations that any serious attempt at a hydrogen freight network will need.

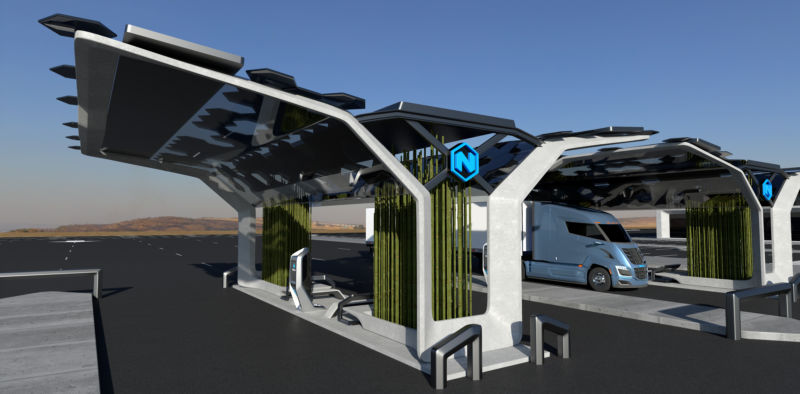

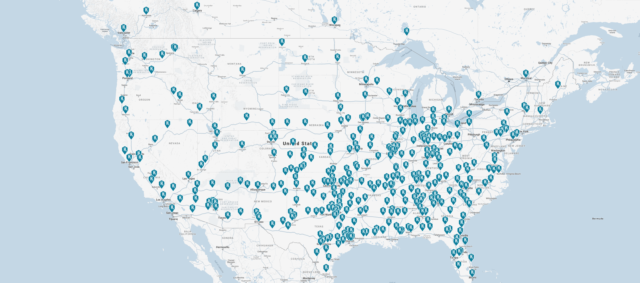

In his presentation this week, Nikola’s Schneider said that every one of the 700 refueling stations that the company plans to build across the US would be powered by “renewable energy supplemented by low-carbon grid energy” using equipment from Nel Hydrogen. Solar panels will be a prominent feature at every Nikola station, and Schneider later added that the company hoped to source a minimum of 30 percent of its electricity from these solar panels and other renewable forms of electricity.

After his presentation, Schneider told Ars that the company would be targeting areas like Arizona, where low-carbon sources of electricity like solar and nuclear power make up a significant portion of grid energy, and areas like the northeast, where hydroelectric power is dominant. But Nikola won’t avoid setting up shop on more carbon-heavy grids—Schneider said where fossil fuel is a major source of power, Nikola will likely buy carbon offsets to keep its fuel “green.”

(Of course, carbon offsets have their own issues. But as more and more utilities move toward renewable and low-carbon portfolios, the number of offsets that Nikola would have to buy in, say, Colorado or Idaho is likely to fall over the years.)

Storage and stations

Nikola’s plan to create hydrogen at every station that it opens also potentially solves a problem that has plagued hydrogen fuel: transportation and storage. Nel will be providing the storage facilities, which it says will ultimately be able to store up to eight tons of H2 per station.

There is some hope that such a massive station would be feasible. Recently, Nikola built a private, one-ton/day station on its property using equipment from Nel, which Schneider said is currently the “largest gaseous H2 vehicle station in the USA.” The company is using the station to conduct heavy-duty fueling testing.

Nikola says that producing and storing hydrogen on site improves its efficiency, especially compared to diesel and gas, which must be produced in refineries and trucked out to stations around the country.

“Fuel cell vehicles are twice as efficient as fossil fuel vehicles,” Schneider told Ars. “Though electric efficiency is higher, the issue is range. With [all-battery] trucks you have to add about seven tons more weight, and if you produce hydrogen from renewables or low carbon, there’s no CO2 or low CO2.”

In response to an audience question, Schneider said an eight-ton-per-day station would require access to 17.6 megawatts (MW) of power, although he didn’t elaborate on annual capacity factors of various types of renewable energy that might service such a station. (That is, 17.6MW of solar energy produces far less electricity in a year than 17.6MW worth of electricity from a nuclear plant running 24 hours a day, seven days a week.)

Nel CEO Løkke added that “the vast majority [of that electricity]… is going into splitting water.” He said that up to 95 percent of the electricity that Nel’s systems use is dedicated to H2 formation. “The rest is almost negligible in compression and cooling,” Løkke said.

https://arstechnica.com/?p=1493013