When San To Chan successfully defended their PhD thesis, they received a gift of saltwater taffy to celebrate and couldn’t help being intrigued by the taffy’s unusual consistency: somewhere between a solid and liquid. That led to experiments investigating the taffy’s rheology—how it deforms in response to applied forces—and how the ingredients and taffy-making process contribute to that rheology. The results are described in a new paper published in the journal Physics of Fluids.

“Taffy is a viscoelastic material—it has properties between a viscous liquid and an elastic solid,” said Chan, now a postdoc in the Fluid Interfaces Group at MIT Media Lab. “Comparing the deformation behavior of commercial taffy to those of different lab-made sugar syrups and lab-made taffies allowed us to identify the most important taffy ingredient (and material structure) that governs taffy rheology.”

It’s just the latest example of a burgeoning area of research focusing on the science of food—something that’s frequently on the menu here at Ars. For instance, in 2020, physicists examined the physics of wok-tossed fried rice and found that the secret to a perfect dish (i.e., nicely browned but not burnt) was a timely combination of side-to-side and see-sawing motions while cooking. In 2022, MIT physicists coined the term “oreology” for their study of why—when twisting two Oreo cookie halves apart—the creme filling typically sticks to only one chocolate wafer.

The pandemic inspired physicists from the University of Illinois at Urbana-Champaign to investigate the physics of cooking pasta—first conducting home experiments, then repeating those with greater precision in the lab once the university reopened after lockdown. The most surprising finding was that the pasta noodles increased in length the longer they were cooked. There have been a surprisingly large number of scientific papers seeking to understand the various properties of spaghetti, both cooking and eating it—the mechanics of slurping the pasta into one’s mouth, for instance; spitting it out (aka, the “reverse spaghetti problem”); or exploring the question of how to get dry spaghetti strands to break neatly in two, rather than three or more scattered pieces.

Earlier this year, scientists explored whether making kimchi in traditional earthenware vessels known as onggi results in the best kimchi. Answer: it does; the porosity of the onggi’s walls help the most desired bacteria proliferate during the fermentation process. Other scientists have studied the structure of cheese; investigated the composition and flow of gluten-free batter and breads; discovered why strands of honey can get so long and thin as they drip without actually breaking; figured out a way to get cocoa butter to distribute more evenly in chocolate to enhance the perceived texture; studied why Brazil nuts rise to the top of a can of mixed nuts (aka the “Brazil nut effect“); and figured out how to “tune” the flow of Swiss cheese fondue by adding cornflour or wine.

“Studying the physical principles associated with manipulating different foods might, in turn, stimulate discoveries of scientific, engineering, and engineering importance,” Chan et al. wrote in their paper. In the case of saltwater taffy, a better understanding of its rheology, as well as that of other sugar-based confections, could enable artisans “to manipulate the material better, leading to novel techniques for creating designs with high artistic and cultural value, as well as enhanced control of their texture and mouthfeel.”

Saltwater taffy is a bit of a misnomer in that salt water isn’t an ingredient. Taffy is just sugar, corn starch (for a smooth texture), corn syrup and butter (as interfering agents to keep the sugar from crystallizing), glycerine (for a creamy consistency), salt, water, food coloring, and flavorings. The (likely apocryphal) story behind the name involves an Atlantic City candy store owner in the 1880s named David Bradley. His store on the boardwalk flooded in 1883, soaking his products, and when a little girl came in asking for a piece of candy, Bradley joked that all he had was “saltwater taffy.” The name stuck, and the candy became immensely popular; it’s still a staple of US coastal towns.

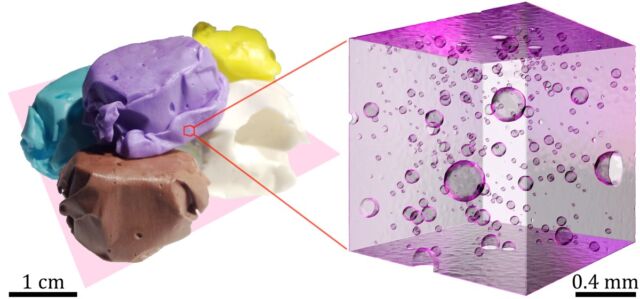

The basic taffy ingredients are combined and brought to a boil—traditionally in copper kettles—then laid out on marble slabs to cool. When it is cool enough to handle, the taffy is pulled and stretched into large bands, trapping air between the layers to ensure the final candy stays soft and chewy. Early on, this was done by hand in so-called “taffy pulls,” but as the 20th century dawned, there were many US patents for taffy-pulling machines to handle this strenuous work.

https://arstechnica.com/?p=1967089