A team of engineers at the University of Maryland has built a three-fingered soft robotic hand that is sufficiently agile to be able to manipulate the buttons and directional pad on a Nintendo controller—even managing to beat the first level of Super Mario Bros. as proof of concept, according to a recent paper published in the journal Science Advances. The same team also built two soft robotic turtles (the terrapin turtle is UMD’s official mascot) using the same multimaterial 3D-printing process that produced the robotic hand.

We traditionally think of robots as being manufactured out of hard, rigid materials, but the subfield of soft robotics takes a different approach. It seeks to build robotic devices out of more flexible materials that mimic the properties of those found in living animals. There are huge advantages to be gained by making the entire body of a robot out of soft materials, such as being flexible enough to squeeze through tight spaces to hunt for survivors after a disaster. Soft robots also hold strong potential as prosthetics or biomedical devices. Even rigid robots rely on some soft components, such as foot pads that serve as shock absorbers or flexible springs to store and release energy.

Harvard researchers built an octopus-inspired soft robot in 2016 that was constructed entirely out of flexible materials. But soft robots are more difficult to control precisely because they are so flexible. In the case of the “octobot,” the researchers replaced the rigid electronic circuits with microfluidic circuits. Such circuits involve regulating the flow of water (hydraulics) or air (pneumatics), rather than electricity, through the circuit’s microchannels, enabling the robot to bend and move.

Although this solution is ingenious, it brings its own set of challenges. These include the high cost (clean room facilities are required) and time necessary to fabricate those microfluidic systems and then integrate them with the system as a whole. “Recently, several groups have tried to harness fluidic circuits to enhance the autonomy of soft robots,” said co-author Ruben Acevedo. “But the methods for building and integrating those fluidic circuits with the robots can take days to weeks, with a high degree of manual labor and technical skill.”

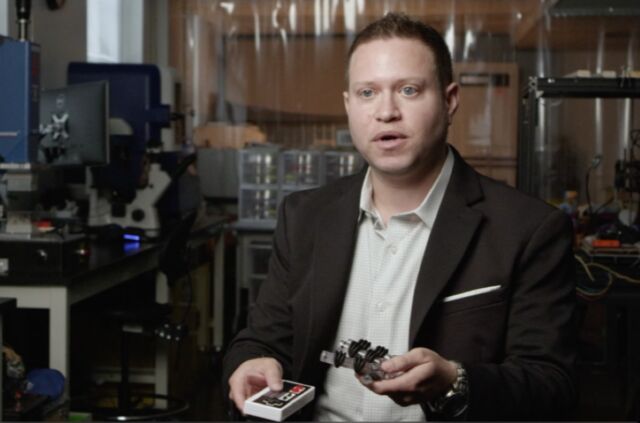

As an undergraduate, Acevedo worked in the lab of University of Maryland mechanical engineer Ryan D. Sochol, who was interested in moving beyond having to manually connect fluidic circuitry components to soft robots in favor of embedding these functions directly in the soft robotic systems. His team found the answer in PolyJet 3D printing, in which several different layers of materials are stacked on top of each other. The printer sets down one liquid layer, lets it solidify, then sets down the next layer, and so on.

“The incorporation of materials that differ in rigidity serves to enhance performance by allowing the material properties of specific features to be tailored to complement desired functionalities,” Sochol et al. wrote in their paper. Components like diaphragms and O-rings must be able to deform during operation, so a soft rubber-like material was used to make them, while a more rigid, plastic-like material was chosen to make components that need to be stable (fluidic channels, access ports, and structural casings, for instance). Finally, the team used a water-soluble material to serve as scaffolding during the printing process, which was then removed from both the exterior and internal voids and channels—first by dissolving the stuff with water, then manually removing whatever scaffolding material remained.

Microfluidically controlled soft robots typically require distinct control inputs for every independently operated soft actuator. By integrating the fluidic circuit, the UMD team could operate the hand by varying the pressure strength between low, medium, and high. In other words, a single source of fluid could send different signals just by changing the pressure, so that each finger could move independently. Even better, the one-step 3D-printing process for the hand and the two turtle-bots—encompassing soft actuators (moving parts), the fluidic circuits, and robot body—took a matter of hours, not days or weeks.

The team tested the performance of the robotic hand by having it play Super Mario Bros. To make Mario walk, the team used a low pressure, so only the first finger pressed the controller. The researchers used a medium pressure to make Mario run and a high pressure to make the hand press the correct button on the controller to get Mario to jump.

As for why they chose Super Mario Bros., Sochol told Scientific American that it was the very first Nintendo game he had played as a child. But the choice wasn’t just a matter of nostalgia. The timing and specifics of the game are well-established; the robot hand simply needed to time its responses in accordance with the preprogrammed moves. And there are actual consequences for failure: a single mistake will cost Mario a life. The hand performed so well, it was able to successfully beat the first level of the game in less than 90 seconds.

“We are freely sharing all of our design files so that anyone can readily download, modify on demand, and 3D print—whether with their own printer or through a printing service like us— all of the soft robots and fluidic circuit elements from our work,” said Sochol, who estimates that printing one’s own soft robots would cost about $100 using the team’s software on GitHub. “It is our hope that this open-source 3D printing strategy will broaden accessibility, dissemination, reproducibility, and adoption of soft robots with integrated fluidic circuits and, in turn, accelerate advancement in the field.”

DOI: Science Advances, 2021. 10.1126/sciadv.abe5257 (About DOIs).

Listing image by University of Maryland

https://arstechnica.com/?p=1782874