Physicists at Leiden University in the Netherlands have created a 3D-printed microscopic version of the USS Voyager from the Star Trek franchise, according to a recent paper in the journal Soft Matter. These kinds of synthetic “microswimmers” are of great interest to scientists because they could one day lead to tiny swimming robots for autonomous drug delivery through the bloodstream, or for cleaning wastewater, among other potential applications. Such studies could also shed light on how natural “microswimmers” like sperm and bacteria travel through the human body.

Because of their small size, microswimmers face unique challenges when they move through fluids. As we’ve reported previously in the context of different research, biological microorganisms live in environments with a low so-called Reynolds number—a number that predicts how a fluid will behave based on the variables viscosity, length, and speed. Named after the 19th-century physicist Osborne Reynolds, the concept is especially useful for predicting when a fluid will transition to turbulent flow.

In practical terms, it means that inertial forces (e.g., pushing against the water to propel yourself forward while swimming) are largely irrelevant at very low Reynolds numbers, where viscous forces dominate instead. So because bacteria or sperm swim at low Reynolds numbers, they can barely coast any distance at all if you push them to set them in motion. It’s akin to a human trying to swim in molasses.

“By studying synthetic microswimmers, we would like to understand biological microswimmers,” co-author Samia Ouhajji told CNN. “This understanding could aid in developing new drug delivery vehicles; for example, microrobots that swim autonomously and deliver drugs at the desired location in the human body.”

Shape turns out to be a significant factor affecting the motion and interactions of microswimmers, and that is the focus of this latest paper. “Shape and motion in synthetic and biological micro swimmers are intimately connected,” the authors wrote. Prior studies have shown that L-shaped particles follow circular trajectories, for instance. And in 2016, scientists at Southern Methodist University built microswimmer robots resembling a chain of magnetic beads, whose movement could be controlled via a rotating magnetic field. They found that microswimmers of different lengths had different swimming properties. Most notably, longer ones swim faster.

The Leiden team needed a robust method of making microswimmers in a variety of complex shapes. Synthetic microswimmers are typically made via chemical or evaporation techniques, which, while effective, limit the possible shapes to spheres or rod-like colloids. Biological microswimmers are far more diverse and asymmetrical with regard to shape. So the Leiden researchers opted to use “two-photon polymerization,” or 2PP, a method that enables the 3D printing of microstructures while still having some flexibility in terms of shape and symmetry. It also allowed them to control how a particle is oriented relative to the fused-silica substrate on which it is printed, giving them extra control over the resulting motion.

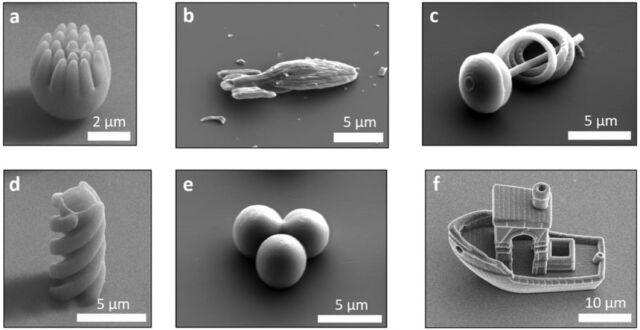

“The potential of 2PP to create microswimmers with a wide range of geometries is immense, allowing the production of almost any desired shape,” the authors wrote. According to co-author Daniela Craft, a Leiden University physicist, the team focused a laser inside a droplet and used it to “write” whatever structure they desired. They were able to create a variety of shapes at the micrometer scale with a high-resolution 3D printer. Once printed, the objects were placed in propylene glycol methylether acrylate for 30 minutes, and dipped five times in isopropanol. As a finishing touch, each structure was coated with a catalytically active nanolayer of platinum/palladium.

The team started by printing spherical particles in the 1 to 10 micrometer range as proof of principle and were able to conclude that 4 micrometers was the lowest they could go and still produce reasonably spherical shapes. Next, they showed that, when placed in water, their spherical particles exhibited Brownian motion, the random movement of particles in a fluid as they constantly collide with other molecules—i.e., they behaved like true colloids. (Fun fact: one of the seminal papers Albert Einstein published in 1905—his annus mirabilis —modeled individual water molecules as a mechanism for the observed random motion of pollen particles in a puddle.)

Then the Leiden scientists placed their microswimmers into a water and hydrogen peroxide solution; the platinum/palladium coating reacted with the solution to create self-propulsion, or active motion. “The difference in the passive trajectories in water and those in hydrogen peroxide solution show that through a simple coating procedure, 3D printed colloids can be made active,” the authors wrote.

For the next phase of their research, the Leiden team expanded their repertoire to 3D print more complex structures: a spiky sphere, a spiral, a helix, and a so-called “3DBenchy” boat measuring 30 micrometers long—short for “benchmark,” a structure commonly used to test 3D printers to see how well they handle fine detail. The Benchy boat, for example, sports such challenging geometrical features as portholes and an open cabin.

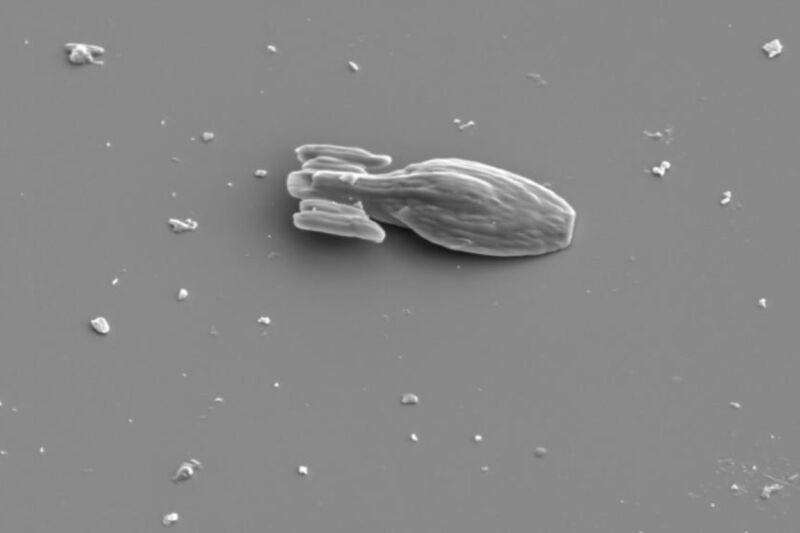

And of course, they made the micro version of the USS Voyager, measuring just 15 micrometers long. That was at the behest of co-author Jonas Hoecht, who was given the choice of printing any 3D shape he liked for the final sample. Hoecht is a diehard Star Trek fan and picked the Voyager. All the 3D-printed micro objects were imaged using a scanning electron microscope (SEM).

“We hope to learn about what is now a good design principle for creating a little drug delivery vehicle—if you have a little particle that goes to a specific part of the body to deliver drugs, then it has to propel itself, and it may have to deal with the environment in your body, which is very complex,” co-author Daniela Kraft told CNN. “What we are trying to answer is: what would be a good design? What would be a great shape so that it can go around and be efficient?”

The team’s research demonstrated that particles created in a helix shape showed the most promising movement. “When it moves forward, often it needs to rotate, and that helps, for example, to speed it up,” said Kraft. “If you think about applications, if you want to have a little machine that goes somewhere, it might be more useful to have a helix shape, because it swims faster.”

DOI: Soft Matter, 2020. 10.1039/d0sm01320j (About DOIs).

https://arstechnica.com/?p=1723261