Thirty years ago, a botanist in Germany had a simple wish: to see the inner workings of woody plants without dissecting them. By bleaching away the pigments in plant cells, Siegfried Fink managed to create transparent wood, and he published his technique in a niche wood technology journal. The 1992 paper remained the last word on see-through wood for more than a decade, until a researcher named Lars Berglund stumbled across it.

Berglund was inspired by Fink’s discovery, but not for botanical reasons. The materials scientist, who works at KTH Royal Institute of Technology in Sweden, specializes in polymer composites and was interested in creating a more robust alternative to transparent plastic. And he wasn’t the only one interested in wood’s virtues. Across the ocean, researchers at the University of Maryland were busy on a related goal: harnessing the strength of wood for nontraditional purposes.

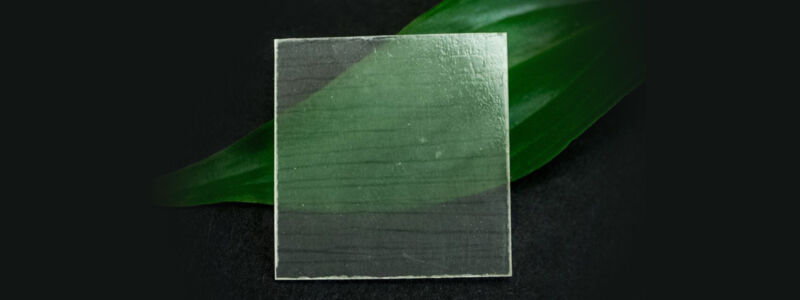

Now, after years of experiments, the research of these groups is starting to bear fruit. Transparent wood could soon find uses in super-strong screens for smartphones; in soft, glowing light fixtures; and even as structural features, such as color-changing windows.

“I truly believe this material has a promising future,” says Qiliang Fu, a wood nanotechnologist at Nanjing Forestry University in China who worked in Berglund’s lab as a graduate student.

Wood is made up of countless little vertical channels, like a tight bundle of straws bound together with glue. These tube-shaped cells transport water and nutrients throughout a tree, and when the tree is harvested and the moisture evaporates, pockets of air are left behind. To create see-through wood, scientists first need to modify or get rid of the glue, called lignin, that holds the cell bundles together and provides trunks and branches with most of their earthy brown hues. After bleaching lignin’s color away or otherwise removing it, a milky-white skeleton of hollow cells remains.

This skeleton is still opaque, because the cell walls bend light to a different degree than the air in the cell pockets does—a value called a refractive index. Filling the air pockets with a substance like epoxy resin that bends light to a similar degree to the cell walls renders the wood transparent.

The material the scientists worked with is thin—typically less than a millimeter to around a centimeter thick. But the cells create a sturdy honeycomb structure, and the tiny wood fibers are stronger than the best carbon fibers, says materials scientist Liangbing Hu, who leads the research group working on transparent wood at the University of Maryland in College Park. And with the resin added, transparent wood outperforms plastic and glass: In tests measuring how easily materials fracture or break under pressure, transparent wood came out around three times stronger than transparent plastics like Plexiglass and about 10 times tougher than glass.

“The results are amazing, that a piece of wood can be as strong as glass,” says Hu, who highlighted the features of transparent wood in the 2023 Annual Review of Materials Research.

The process also works with thicker wood but the view through that substance is hazier because it scatters more light. In their original studies from 2016, Hu and Berglund both found that millimeter-thin sheets of the resin-filled wood skeletons let through 80 to 90 percent of light. As the thickness gets closer to a centimeter, light transmittance drops: Berglund’s group reported that 3.7-millimeter-thick wood—roughly two pennies thick—transmitted only 40 percent of light.

The slim profile and strength of the material means it could be a great alternative to products made from thin, easily shattered cuts of plastic or glass, such as display screens. The French company Woodoo, for example, uses a similar lignin-removing process in its wood screens, but leaves a bit of lignin to create a different color aesthetic. The company is tailoring its recyclable, touch-sensitive digital displays for products, including car dashboards and advertising billboards.

But most research has centered on transparent wood as an architectural feature, with windows a particularly promising use, says Prodyut Dhar, a biochemical engineer at the Indian Institute of Technology Varanasi. Transparent wood is a far better insulator than glass, so it could help buildings retain heat or keep it out. Hu and colleagues have also used polyvinyl alcohol, or PVA—a polymer used in glue and food packaging—to infiltrate the wood skeletons, making transparent wood that conducts heat at a rate five times lower than that of glass, the team reported in 2019 in Advanced Functional Materials.

https://arstechnica.com/?p=1989784