Key insights:

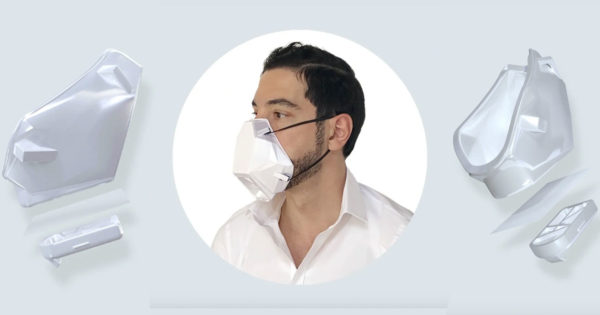

As social distancing measures were ramping up in late March, freelance creative director Tito Melega and German product designer Amine Arezki had a flash of inspiration during an impromptu lunchtime Zoom gathering hosted by a mutual friend.

Arezki was discussing the use of 3D printing to help fill some of the shortages in medical masks caused by the COVID-19 pandemic. Melega happened to sit on the advisory board of a Knoxville, Tenn.-based 3D printing startup called Ascend Manufacturing.

Soon, the pair of previous strangers were holding daily Zoom discussions along with Ascend CEO and founder Justin Nussbaum. They fleshed out an idea for an open-source 3D-printable mask design, culminating in a project called A Mask For All.

“It really opened my eyes to the possibilities of [3D printing]—and also the limitations of it,” Melega said. “I very quickly had a crash course on [polyactic acids] and different filaments and flexible versus rigid and permeability.”

The project is one of several that, in combination, seem to be fulfilling the promise of 3D printing—a technology that has long been rich in potential, but niche in practice. Its flexibility and dynamism are needed more than ever as the United States struggles to produce the personal protective equipment and medical supplies needed to supply both frontline healthcare workers and everyday people forced into new hygienic routines.

“If you do it right, and you have the solutions in your own backyard, you can load a piece of software and build yourself either a mask or or a solution to build a mask or ventilator in a couple hours as opposed to a couple weeks,” said Jake Duhaime, producer of 3D printing podcast 3DPod and spokesperson for 3D printing pen maker 3Doodler.

The technology has existed for years now, but a host of factors, like the steep price of equipment and material constraints, have largely kept it from being adopted widely by manufacturers or consumers beyond a small set of hobbyists and startups. Brand marketing campaigns involving the tech have been few and far between, including an Ikea 3D printing project to make furniture more accessible and a social good effort exploring 3D-printed guns.

But as companies struggle to repurpose factories or ship supplies from overseas, advocates for 3D printing technology are hoping the pandemic could be the moment at which it finally gains a critical mass.

“If you look at 3D printing, it’s kind of at where personal computers were in the 1970s—not quite there in terms of everyone having adapted to it, but important enough to work businesses understand it’s part of their future,” said Duhaime. “I think this will be a catalyst.”

Digital manufacturing may also be particularly well-poised for this moment in terms of its adoption thus far. As the cost of 3D printing has been steadily dropping and the equipment improving, certain industries have already been turning to it to fill key needs, including healthcare, construction and automative parts according to a report this month from GlobalData.

More traditional injection-molding manufacturing still beats 3D printing in terms of price and scale, but the technology is much better suited for situations in which customized items are needed in a pinch.

“3D printing has leapt from the proof-of-concept stage to a viable manufacturing alternative,” said GlobalData analyst Venkata Naveen. “This year will be game-changing for 3D printing technology amid the COVID-19 pandemic. …The current scenario of fragile supply chains will fast-track the development of a digital manufacturing ecosystem, driven by 3D printing technology.”

The U.S. Food and Drug Administration has also relaxed some regulations on medical equipment to more nimbly serve the needs of the pandemic frontlines, reducing regulatory expenses that might otherwise discourage smaller companies without big scale.

https://www.adweek.com/creativity/3d-printing-enters-a-game-changing-era-as-supply-shortages-spark-creative-solutions/