It all started with Ploopy.

“What a goofy name for a trackball,” I thought to myself as I tweeted. “Ploopy,” several people responded. One friend commented that it looked like MS Trackball Explorer, an iconic trackball. “It’d be a funny gag if I got really into having a trackball,” I thought. (I was not a “trackball person.”) The problem is that any bit taken to its logical conclusion just becomes sincerity and a year later I not only bought a Ploopy, but completely rebuilt it, and went so far down the trackball rabbit hole that I had a new one manufactured entirely from scratch.

I have become a Trackball Sicko.

If you didn’t live through the ’90s and have never heard of a trackball, that’s more than understandable. For the uninitiated, a trackball is a pointing device similar to a mouse, except you use a tiny rolling sphere to move your cursor instead of moving the entire device. Trackballs used to be much more commonplace back in the day, and trackball diehards say it can be an easier and more ergonomic way of interfacing with UI, particularly for people with mobility impairments.

Goofy name aside, the idea motivating Ploopy mirrors something that has been going around in the DIY keyboard community for a while; namely, open-source design and flexible firmware. The files for all the products Ploopy sells are on Github for anyone resourceful enough to have them fabricated, and the device itself runs QMK, one of a few lightweight keyboard firmwares out there. The devices are easy to remap and customize yourself without installing invasive bloatware like Logitech G Hub or Razer Synapse, and many of the Ploopy products use the same sensors and switches found in high-end mice.

This is a world I was more than familiar with after having built a split ergonomic keyboard called a Sofle. The thing that sold me on the Ploopy was the Nano, a tiny, buttonless trackball with a 1.5-inch snooker ball that fit right in between the two halves of my split keyboard. For 45 bucks CAD and just a tiny bit of soldering, I could have a tiny little guy placed neatly in the middle of my keyboard for making little finite adjustments on-screen instead of having to lumber over to my mouse every single time I needed to change something. What’s more, because I was already a split keyboard freak, I could program a button on each half of the keyboard using layers, to act as mouse buttons one, two, and three.

“What the hell,” I said, and then I clicked buy.

The Nano turned out to be everything I expected and far more. I assembled it and not only did it make doing tiny adjustments easier, it was immediately intuitive to my entire, freakish workflow. Editing was easier. Switching windows became easier. I still had my mouse, a trusty Logitech G Pro, but I found myself going to it less and less for scrolling. I was in love.

Then I found out about the mods.

Another element of the open-source design philosophy motivating Ploopy and the keyboard community at large is iteration. Ploopy’s products are 3D printed, and since all the documents are out there, you can 3D print whatever housing you want for your Ploopy if you have access to a nice enough printer.

The first mod that made my jaw drop was one by user sickbabies on the Ploopy subreddit (I am aware of how absurd those two words sound together). A beautiful sand-colored trackball with a stainless steel ball bearing specifically meant to match their headphones and their keyboard, a tan Le Chiffre. What’s more, my good friend and fellow trackball sicko Jon informed me that people had gone beyond the simple 3D printed roller bearings that came with the Ploopy and reprinted their housings to use BTUs, or “Ball Transfer Units,” which can move more freely than static or roller bearings and with far less friction. Eventually somebody uploaded a BTU mod for the Ploopy Nano, and the path for me was clear. I ordered some BTUs, a steel ball, and made my preparations.

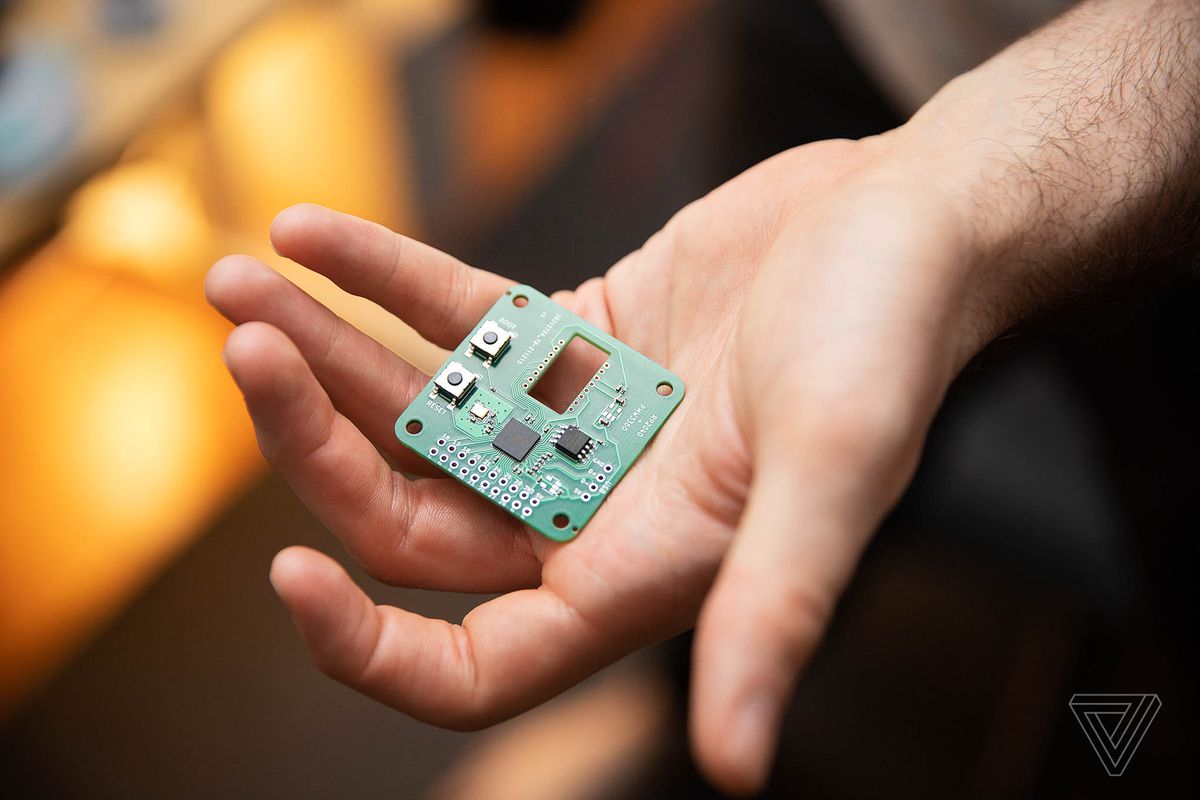

It turned out, however, that Ploopy is not the only game in town. While I planned my upgrade, I caught wind of the works of Jfedor2, a Redditor who had created their own open-source PCB [printed circuit board] and breakout board for rapidly prototyping new trackballs and mice using the relatively new but game-changing RP2040 chip by the Raspberry Pi Foundation. As I’ve written this, he’s uploaded at least 10 absolutely alien looking trackballs and mice, including a vaguely pyramidal one with a scroll wheel, a trackball with two trackballs, a trackball where you can twist the ball to scroll, and a spherical trackball perfect for orb pondering.

Fabricating the circuit board for a mouse is not as difficult as it used to be. Provided you have the Gerber files (a vector file of a PCB), a BOM (bill of materials) and a CPL file (component placement list), manufacturers (like JLCPCB or ALLPCB) will not only print out your circuit board for you, they’ll sell you all the parts you need and solder those pain-in-the-ass little surface mount components right on the board for you (provided there isn’t, let’s say, a parts shortage). I put an order in for five trackball PCBs, and my aforementioned fellow trackball friend printed me out some retro-looking, clear-and-seafoam shells for not only my Ploopy Nano, but a big brother called Trackball 7 that uses a full-sized billiard ball.

Once assembled, both were gorgeous. The BTUs on the newly upgraded Nano rolled smoothly and easily, a clear improvement over the base model, and the clear plastic exuded an unearthly glow. But not everything went off without a hitch. While the chrome steel ball I had gotten for it felt wonderful to the touch, the surface required a little breaking in to get it to track properly. Some on Reddit fixed this by sanding theirs down to take the shine off of the finish, and another recommended using an acrylic topcoat and another chemical bluing. This is probably why traditional trackball makers like Logitech use a sparkly trackball instead.

I had made a fateful error while having Jfedor’s trackball PCBs manufactured: Two of the voltage regulators on the board were terminally backordered, so I tracked down equivalents on Digi-Key (an electronic component distributor), soldered those tiny suckers on, and loaded up the firmware. Now I have a fully functional and very weird-looking trackball in my home.

But supply chain issues aside, I was happy. I had taken something and customized it to be truly my own from the ground up, and in the process of making these objects, I not only had gained more confidence in my abilities, but a clear understanding of how I could take the torch and build something new too. It turns out there’s very little stopping you from making your own trackball, if you’re that kind of sicko.

But of course, once you’re down this path there’s no rest. Sure, these bearings are pretty smooth, but could they be… smoother? I could apply a dry coating of tungsten disulphide to the BTUs, like I’d read about on gun forums. Or I could have my trackball coated with something like Cerakote or DLC (diamond-like carbon)? Or hell, what if I just built a keyboard that has a trackball in it, like the Oddball, the Splitballer, the Keyball46, the ino, or that one I saw some early mockups of. I do also have those circular trackpads in the mail that I bought after talking to Freznel about their board — maybe that’s the way to go? And now that I know how to swap out a microswitch, why not disassemble my mouse and replace the switch with those silent ones I impulse-ordered from AliExpress?

On second thought, maybe you don’t want to be a trackball sicko. Look at what it’s done to me.

https://www.theverge.com/22958439/trackball-diy-building-ploopy